The process leading to the accomplishment of your project is complex, but thanks to our know – how it will look simple and quick. The project for us is led by your needs: starting from there infact, we turn your project or even just your idea into a standard product.

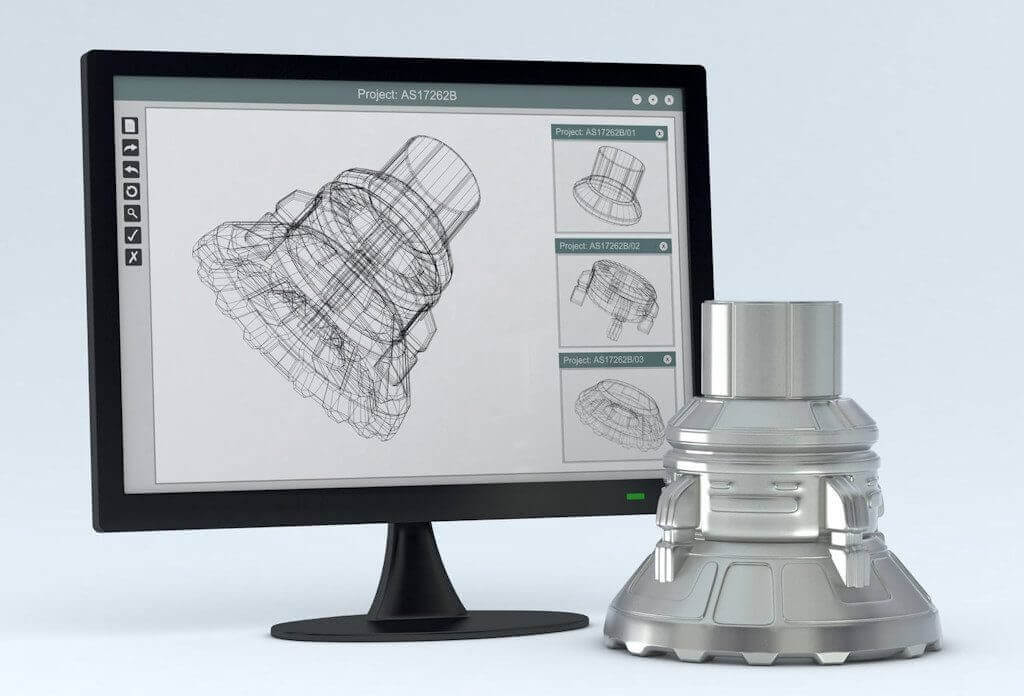

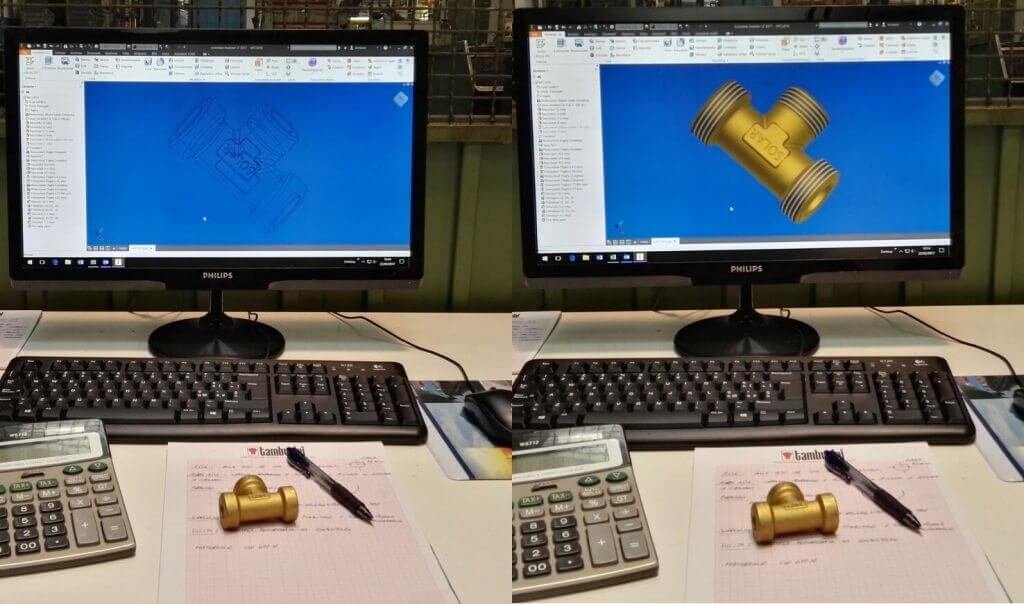

When a customer submits us project for a new product our tecnichal department deals with all of the aspects connected to its engineering: thanks to its expertise, to its skills and to the sophisticated equipments it can count on, our technical department developes all of the necessary aspects to the achievement of the product, defining the bill of material and the work-cycles, defining the relevant tools, from the moulds to the production tools and to all of the equipments required for all of the working stages, in connection with the technical department of the customer and with MFC production units.

Our technical department is therefore able to support our customer during the engineering stage itself, at the purpose to find out together the best technical solution, warranting the fixed quality standards, saving up production costs at the same time.

After the engineering , the first step to achieve the product is forging the brass bar. Thanks to the perfect integration within the production supply chain, we take care directly of the creation of moulds and tools, as well as of the heat forging stage for components 40 gr.through 10 kg. For those items which features do not allow a heat forging work, we rely on a foundry able to achieve che casting items according to the state-of-the-art.

The actual working is carried out in our production units on behalf of transfers, most of which are equipped by robotized loading and unloading.

Beyond our internal working, we are also able to supply engineering workings accomplished by specialized machines such as single spinding machines, multi-spindling lathes, sliding-head lathes, work stations.

Once the real production stage is over, the pieces achieved may be submitted to some ulterior treatment processes, such as pickling, cleaning, nickeling, chromium plating, anodization and vernishing.

The finished products may be packed up according to the customer requirements, through a service of bagging, labeling and placement in boxes or cardboxes.

All of the stages of the productive process are carefully monitored according to the guidelines of the quality system to provide the customer with a product perfectly complying with the customer’s expectations.